A FACTORY in Prai has agreed to help mass produce the face shield that Penang engineer Louis Ooi Shiong Yirk had invented for medical personnel to use when they test patients for Covid-19.

Prestige Dynamics Industries (PDI) Sdn Bhd will take part in the face shield project that Ooi, 28, has been collaborating with the Penang Science Cluster (PSC), a non-profit organisation promoting science and technology, innovation and technopreneurship among the young.

Currently, Ooi and PSC, with the help of over 30 members of the public who have 3D printers at their homes throughout Penang, are able to make about 100 to 200 plastic visors per day for the face shield.

The visor is the core piece of three basic components of the face shield.

The other two components are the elastic band and a standard A4 transparent PVC sheet, which are both easily accessible and obtainable from a stationery shop.

According to Ooi, PDI will fabricate a mould costing about RM10,000 to RM15,000 for PSC free of charge and will also donate the first 10,000 visors to PSC when it starts production probably next week.

Impressed with Ooi’s creation, Penang Chief Minister Chow Kon Yeow said the state government would provide a RM60,000 grant for Ooi and his PSC team to cover the cost of producing 2,000 face shields daily for a month.

Chow said the face shield, which is safe, comfortable to wear, affordable and easy to make, would be provided to all government hospitals and clinics.

“We’re thankful to the state for their support. We’ve now to move onto the next stage of mass production. We actually need to do plastic injection moulding and that is why we have approached PDI,” said Ooi in an interview with Buletin Mutiara at Penang Science Cluster which is located at Wisma Yeap Chor Ee in George Town.

“For now, we are trying to cope with the demand for Penang. But we don’t stop here. We will try to reach out to other states in Malaysia. If they need these visors, we are ready to help.”

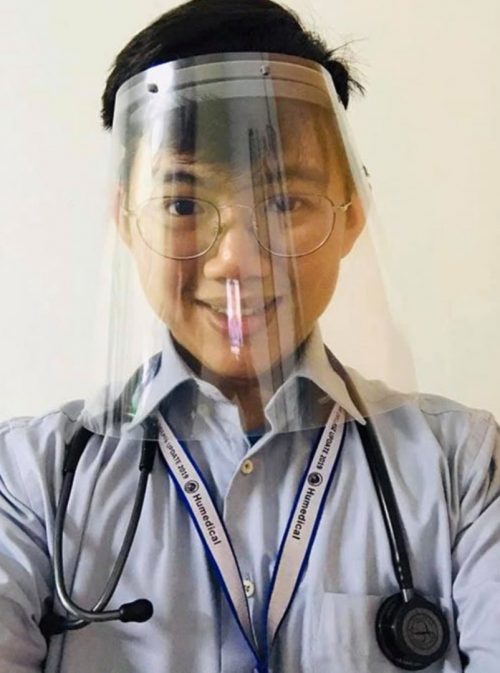

Wearing a face shield will further protect medical personnel when they test a person for Covid-19.

Medical personnel who do not wear face shield but only N95 with goggle when inserting a cotton swab into a patient’s nose risk infection. This is because the patient will naturally sneeze after a cotton swab is inserted deep into his or her nose.

Ooi came out with his first face shield on March 24 after the idea was first mooted by PSC operations manager Aimy Lee in their Whatsapp group among PSC members.

In the group, Lee had shared the efforts done by overseas communities in supplying face shields to frontliners and she suggested that was something the group could also do.

Ooi was then inspired to follow up after one of his mentors, Anita Tan Hai Poo, who is also a member of the group, spoke to him and also sent him images of visors and DIY face shields being used in Malaysia.

The first person Ooi consulted was his friend, Dr Seet Jia Sheng, for feedback and the requirements of a practical and applicable face shield.

“After a few rounds of discussion with Dr Seet, we came out with the first version of the face shield.

“He immediately fell in love with it. He shot a video and posted it on his FB.

“Dr Seet himself tested it. He is a doctor from the General Hospital and he volunteered himself to be in the Covid-19 screening team. He is one of the team leaders,” Ooi said.

It took Ooi about three hours to come out with his first design plus several fitting tests.

Since then, Ooi has been meeting doctors from different departments to make improvement on the design. The present face shield is his third design. The material cost is RM2.50 for each face shield.

When he started, Ooi tried to make a face shield that was comfortable to wear and flexible to fit every size of forehead. From feedback, Ooi made improvement to the visor by closing it up to prevent any aerosol from dropping into the face shield. Then, he further made it easier for the user to take out the rubber strap from the hook.

Ooi said the visor is reusable after being disinfected while the plastic sheet could be disposed after being used.

“We’ve tested the visor with about 100 cycles of washing with solutions that we got them from hospitals. They usually use the solutions to clean all their medical equipment.

“We don’t want to make any medical claim. It is not the hospital which gives any approval for all this. This is a kind of face shield for general use.

“When we design this, we get feedback from the doctors and keep on improving it all over time. They don’t represent any organisation or the Penang Hospital. It’s from a personal kind of discussion,” Ooi stressed.

While doing his tertiary education at KDU, Ooi volunteered himself to help set up PSC and also conduct workshops.

“At PSC, we always focus on design thinking. We look at what is the problem and try to think of ways to solve it. Without PSC, I won’t be here today,” Ooi said.

After his graduation, Ooi started his own company, known as 12Make, which builds customised software and automation machines for industries.

Lee said PSC has to date distributed 1,300 plastic visors and more than 7,000 plastic sheets to various hospitals and clinics in Penang.

They included Penang Hospital, Seberang Jaya Hospital and Bukit Mertajam Hospital, Klinik Kesihatan Tanjung Bungah, Bayan Lepas, Jalan Perak, Sungai Dua, Bandar Tasik Mutiara, Bukit Mertajam, Penang Island City Council (MBPP), Doctors Without Borders, non-profit dialysis centres, and two government clinics from Perak.

Lee said PSC’s appreciation also goes to the community, individuals and companies for all their support.

She commended the over 30 members of the public for spending their time as well as material to help PSC print the visors from their 3D printers and the over 200 volunteers who signed up in less than two days via a crowdsourcing effort.

At present, PSC staff members and interns take turns to help punch holes on the elastic band, cut the plastic sheets and pack the items. The volunteers are on standby and they may be required to help out once the mass production of the face shield begins.

Lee also thanked companies like Intel, Mini Circuits, Keysight Technologies, Agilent Technologies, Jabil and Dream Catcher apart from the state government for providing financial support.

She also praised some 40 individuals who have contributed a total sum of RM40,000 for the project.

Story by K.H.Ong

Pix by Adleena Rahayu Ahmad Radzi and courtesy of Penang Science Cluster